Biofuel Overview

What is Biopower?

![]() Simply put, it’s a way to extract energy from organic material! Biopower or “biomass power” is the use of biomass to generate electricity. Most of the biopower plants in the world use direct-fired systems. They burn bioenergy feedstocks directly to produce steam. This steam is usually captured by a turbine, and a generator then converts it into electricity. In some industries, the steam from the power plant is also used for manufacturing processes or to heat buildings (these are known as combined heat and power “CHP” facilities). A common method to produce power from biomass is “gasification”.

Simply put, it’s a way to extract energy from organic material! Biopower or “biomass power” is the use of biomass to generate electricity. Most of the biopower plants in the world use direct-fired systems. They burn bioenergy feedstocks directly to produce steam. This steam is usually captured by a turbine, and a generator then converts it into electricity. In some industries, the steam from the power plant is also used for manufacturing processes or to heat buildings (these are known as combined heat and power “CHP” facilities). A common method to produce power from biomass is “gasification”.

Gasification

Gasification is the use of heat to transform solid biomass or other carbonaceous solids into a synthetic “natural gas like” flammable fuel. Through gasification, we can convert nearly any dry organic matter into a clean burning fuel that can replace fossil fuel in most use situations. Whether starting with wood chips or walnut shells, construction debris or agricultural waste, gasification will transform common “waste” into a flexible gaseous fuel you can be utilized to create green energy.

“Thermochemical” gasification of biomass is a high temperature process (700 to 1,600 degrees Celsius – 1,292 to 2,912 degrees Fahrenheit) in the presence of a gasification medium that converts biomass into a clean fuel gas called producer gas or synthesis gas “syngas“. The syngas can be used for many purposes such as electricity generation, for heat, and when cleaned and upgraded to near pure methane, it can be injected into gas grids. The technology has a higher electrical efficiency than other conversion processes and the produced gas is well suited for cogeneration units, especially small-scale gasifiers.

Around 70 to 80 percent of the energy contained in the feedstock is converted to the energy content of the producer gas (the remaining biproduct being heat). Gasifiers range from just a few kilo-watts (kW) up to a couple of hundred mega-watts (MW).

The Gasification Process

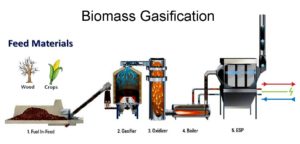

The process involves several steps including pretreatment of the feedstock, the gasification itself, the gas cleaning and the utilization of the gas in a gas engine or any other device depending on its end use. You can review the graphic below for an overview of how the process works (click to enlarge).

| 1. Fuel In-Feed: Wood waste, crops, or other biomass is loaded into the fuel bin and conveyed to a metering bin near the gasifier. | |

| 2. Gasifier: Fuel is processed in stages including drying, pyrolysis, and gasification. The biomass is converted into “syngas” that can be used to displace energy produced by natural gas. | |

| 3. Oxidizer: The syngas is conveyed into the oxidizer where it is combusted with the resulting flue gas directed through a boiler. | |

| 4. Boiler: The boiler produces hot water, steam, hot oil, or hot air depending on the system requirements. In certain systems a back pressure turbine may be added to produce electricity. | |

| 5. ESP: After exiting the boiler the flue gas is cleaned in an electrostatic precipitator to remove up to 98% of particulate matter. |

Biomass Feedstocks

Biomass feedstock typically includes cellulosic biomass, such as wood chips, pellets or wood powder, or agricultural by-products like straw or husks. The process involves air, oxygen, steam or a mixture of these media. Every region has its own locally generated biomass feedstocks from agriculture, forest, and urban sources.

A wide variety of biomass feedstocks are available and biomass can be produced anywhere that plants or animals can live. This makes biomass a flexible and widespread resource that can be adapted locally to meet local needs and objectives. Some of the most common biomass feedstocks are:

| Grains & Starch Crops – sugar cane, corn, wheat, sugar beets, or sweet potatoes | |

| Agricultural Residues – corn stover, wheat straw, rice straw, or orchard prunings | |

| Food Waste – waste produce, or food processing waste | |

| Forestry Materials – logging residues, or forest thinnings | |

| Animal Byproducts – tallow, fish oil, or manure | |

| Energy Crops – switchgrass, miscanthus, hybrid poplar, willow, or algae |